Комментарии:

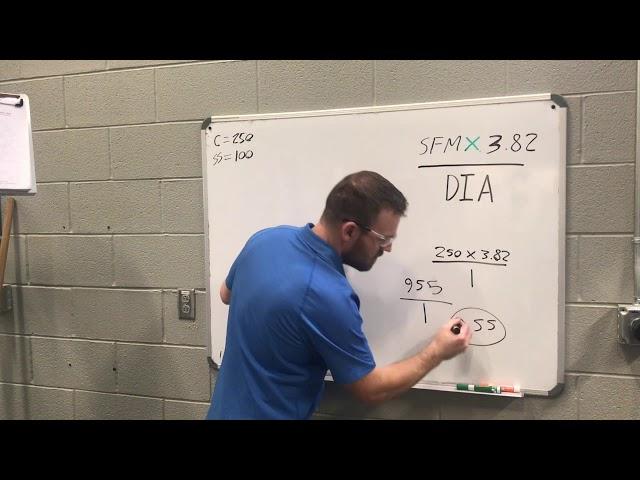

I was cutting tool S7 steel today at 800 sfm, wondering why you’re saying 100 here

Ответить

So now that we have the rpms, how do we get the feeds?

Ответить

i have always seen it as SFM*(pie)3.14/DIA but i feel like 3.82 could run faster and will try it i work with stainless steel which is harder than a lot of meatal.

Ответить

👍🏻

Ответить

What about stainless steel? 250 still gonna work?

Ответить

Question: If my lathe has a one inch shaft, and I attach a 30" disk to it set at 6rpms, then how fast is the outter edge of the disc spinning?

Ответить

Would you happen to know the metric conversion formula?

Ответить

Great video but how do you do the maths with 1 and 3/8 inch ? I’m from the uk and we use mm so I have to convert mm into inch then try and do the maths!

Ответить

How to define rpm in cnc machine if spindle rpm 24000, how much rpm required for portrait designing engraving on iron,

Ответить

1943, 11th edition machinery handbook, its in there. You just have to know what your looking at. Your using 250 with with 1". Easy, convert 1" diameter to circumference, and that looks like this. 1 x pi ÷ 12 = .261. (÷12 because were using feet here.) Now you take your 250 ÷ .261 = 957 rpm. Now your hss, your using 1.5 and 100. Again. its in the machinery handbook, all the way back to 1943. Samething 1.5 x pi ÷12 = .392.

Now take your 100 ÷ .392 = 255 rpm. Im literally looking right at this in my book.

My home workshop lathe has a max rpm of 500 and I do loads of smaller diameter which need loads more, any suggestions? Maybe change drive pulley diameter and lose torque? It is 3 hp 240volt 50 cycle motor single phase.

Ответить

Where can I find the sfm recommendations for the various tools and materials that I work with thats my only issue

Ответить

How to calculate the feed rate for the lathe? Based on formula please

Ответить

So the SFM on a lathe, is whatever the recommended number is of the insert or drill or tap is?

Ответить

What about threading and tapping on manual programming?

Ответить

How you calculated the feed rate onLathe

Ответить

is this spindle speed is maximum ? and is it overcome whirling phenomenon in lathe with single supporting system?

Ответить

how can we find cutting speed according to work piece material without considering spindle speed?

Ответить

Great video. Thank you for the explanation.

Ответить

Bruh...WTF you write backwards and inside-out for...ur 5 looks like an upside down Z crossed with an inbred 2...jeezus phuC...I'm gonna seriously lose my shit on that damn 5!!!

Ответить

If you're drilling on the lathe do you still use the diameter of the material or do you use the diameter of the drill bit for the equation

Ответить

the DIAmeter would be the final diameter OR the initial diameter of the workpiece OR the difference (which is to cut off)??

Ответить

Very helpful straight to the point

Ответить

What if you exceed the speed limit of the machine? What to do?

Ответить

Thanks very helpful

Ответить