Комментарии:

Sooo brilliant!!! Please can you tell me were to find the holder you are using from 4;37? Thanks

Ответить

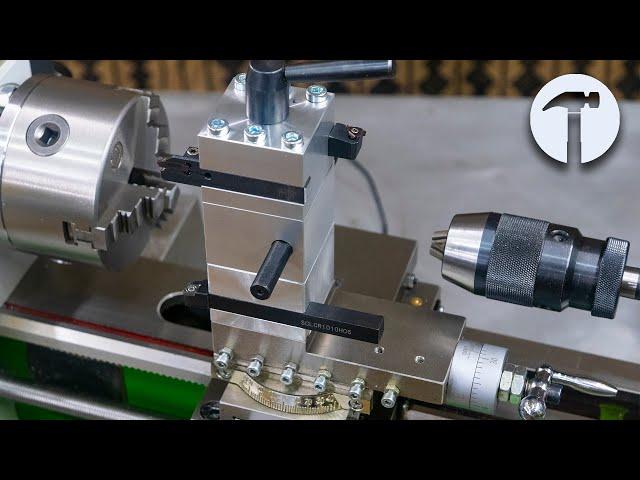

Very good idea! I was going to make one single 4-way, but this is a better idea! I’ll make 3 or 5 at once. Especially one for my boring bar!👍😃 One might add an indexing disc, much like the raising disc you used when milling, and that way also repeat tool angle. (A feature one doesn’t have on a fourway, so not really that necessary.) This is excellent cheap hobby tooling!

Ответить

With carbide inserts, there is no need for an adjustable height of the cutting tool which was necessary when you sharpened yourself the tool. I have done exactly the same on my EMCO Compact5

Ответить

Mantap bos ku. Berapa harga mesin bubut nya

Ответить

С комментами, конечно, было веселее... Но все всё понимают...

Ответить

work clean and executed with excellence, congratulations once again

Ответить

Don't understand how you secure the right positioning after changing the tool holder. I use Multifix on my lathe with electronic leadscrew.

Ответить

Very creative with the lathe. good work!

Ответить

Most people have the two cutting tools they use the most set up on a normal holder .

If you need a quick change you should have got a bigger more industrial lathe with the extra tools and features at the start .

So good to watch 🤓

Ответить

Damn, lots of ways to mill stuff on the lathe, really nice!

Ответить

Good job but for the price of quick change holders nowadays I think you'd be working for less than minimum wage building them.

Ответить

So simple and rigid. I would made one of these from steel for extra strength.

Ответить

how to cast aluminum without pores?

Ответить

That's a good idea! Everyone upgrades their toolpost to a quick change. I could probably hop on a forum and pick up a half dozen of these for little more than shipping cost.

Ответить

Interesting set ups!

Ответить

Nice work.

Ответить

real tired now, hafta lay dwn now.

Ответить

Leaving aside the suitability of aluminium, there is a major issue with this design- there is no positional location of the tool-block, so you loose registration every time you remove the tool. With conventional QC tool holders you can rely on your DRO when you replace the same tool- a major feature.

Ответить

📐📏🔧👍👍

Ответить