Комментарии:

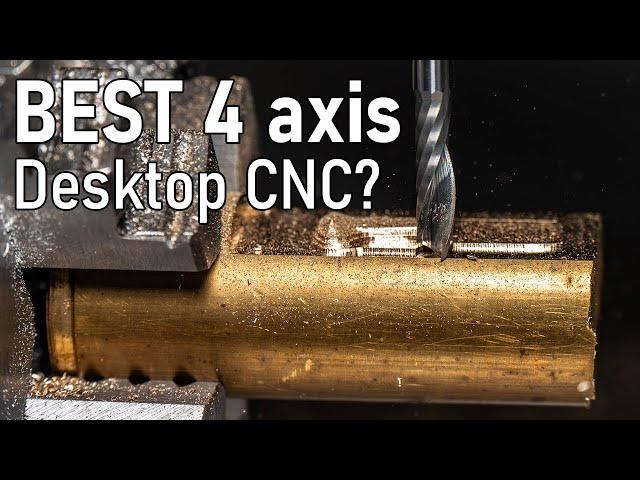

Five grand is not a hobby grade CNC machine, period.

Ответить

I run a $500k+ CNC Plasma Table that is 5 axis and some of the programs can take upwards of 20 mins to load the file. with less than 50k lines of G-Code.

Ответить

Well this is so amazing I think you both inspired me to consider the possibility and to shy away from something so technical. It IS such an interesting tool as you said at the beginning and I did sit through the whole video which is surprising to me for a start.

Ответить

Fusion 360 student version is just a teaser to get you hooked up on Autodesk products so after uni wherever you work you kind off twist their wrist to buy you that, like drug dealers do, you know.

Similar things are done by Catia, Solid Works, Solid Engineering and others.

So I got mad at them all, and after being Autodesk all the way (Autocad than inventor) one day I decided no more shaclkes, at least for my private projects at home.

Now I'm pretty good in FreeCad (I still use the Inventor interface, since I come from there) and I can vouch for this program as generally suitable for machinning jobs, 3D printable jobs, and a miriad of other projects, I designed with the help of FreeCad in the past decade ultralight airplanes, mechanical devices, 3D printers and upgrades, and obviously I 3D printed, machined, cut, welded, drilleed and threaded according to my designs for thousands of hours, ending up making my life a breeze, improving many gadgets (the Quad, the Bike, flight machines, and many things for friends too)

So here is my advice, install FreeCad, is a steep learning curve, but once you are a third way through it you are already almost indipendent, and if you can learn all modules and their functions, the sky is your limit, including in preparing for machining.

You can buy a real mill for that price 🤣

Ответить

Yeah you need to add an air cooling line to that machine. Maybe even an oil mist system for aluminum.

Ответить

The machinery’s handbook has very handy charts for choosing optimal feed&speed for different materials. Can’t recommend it enough, even if this little machine can’t handle a lot of what’s out there.

Ответить

5000 $ for this ? ? lol ...keep dreaming ... this should cost maximum 1000 $

Ответить

Try using an aluminium alloy that has been heat treated to a T6 condition. Softer conditions often lead to tool clogging.

Ответить

My man, cut the bullshit, 5k for a machine is NOT a hobby

Ответить

Hang on is this a sponsored video? You didnt mention it. Did you buy this machine or was it provided to you?

Ответить

Great video. How noisy is the machine one working metal. Would it be compared to a vacuum cleaner kind of noise ?

Ответить

Hi, I’m interested in this machine, and wanted to ask what is the true work volume for 3 and 4 axis… the site says 36cm (Y) x 24cm (x) x 14cm (z) for the 3 axis. And 9.2cm (D) and 24cm (L) for the 4th axis. Wanted to ask if this is what you experienced or is it much smaller than those numbers because for example the 36cm would mean collision with ATC?

Ответить

This kind of milling machine ar standard more then 15 Years ago in dental technic. Tool changer, , 4 th axis all the same.

I don't understand what's new or whats a game changer. ...

Obviously it would have to run slower but, could this handle cutting Titanium and Steel?

Ответить

4k is a steal for this little machine!

Ответить

Would you consider a pocket nc 2 as well? Why or why not? Thanks!

Ответить

This is amazing information, thank you very much for the effort!

Ответить

Would you recommend this as a first CNC? Also what is the noise like, would you be able to get away with using it in an apartment?

Ответить

I have noticed that most of the guys running hobby-type milling machines always have the cutter stuck out too far, keeping the tool's length as short as possible, this will stop deflection. Another good tip is always to climb mill the part, the cutter will last longer, and when milling pockets it will stop the cutter from undercutting the corners through deflection. By the way, I'm an engineer.

Ответить

Would be nice if it was more powerful woukd like to work with harder metals

Ответить

Oooooo... Get new 3d printer, or save up for this?

Ответить

Cool machine! Running your cutters as short as possible is probably one of the best things you can do to improve surface finishes. Some projects won’t permit short tooling but it can make a huge difference, especially on small diameter tool.

Ответить

Excellent review on this machine. Precise and covering aspects of use that matter to users. Definitely a company to watch especially with the co-opted laser module. Future is bright for the manufacturer with pricing as reasonable as this. Bravo, great work.

Ответить

smooth

Ответить

Very cool, in depth video! Thank you for posting your insights and first projects with the machine, they all came out looking very nice ! The 4th axis seems incredibly useful, I should really consider buying one myself. I am currently experimenting with my own (cheap, hobby-) machine and would love to try and recreate your sunflower necklace. Did you model it yourself or find it somewhere on thingiverse? Would love to get my hands on the file :)

Ответить

Haha, so i started watching because of the title, but recognized the voice and realised who it was 🤙🤙

Ответить

Cool video. One slight correction. The true 4th axis troolpaths were never free in Fusion 360. They were available in preview form, but when a user enabled the toolpath in previews ,it was shown that when released it would go into the machining extension.

Ответить

The website doesn't say, what is the max length of the 4-axis add-on? Like how long can a piece of barstock be surfaced?

Ответить

In my opinion, the culprit is one or a combination of three things: dull cutter, or not using the correct style of cutter, not enough horse power in your machine so the cutter isn't able to be pushed where it needs to be, and the properties of the metal itself during machining operations. Aluminum is notorious for gumming up when it gets too hot, this is due to the low melting point of aluminum, the chips will begin to fuse with the cutting edge, this is especially a problem when using a HSS cutter, which is what you appear to be using. You could try switching to a VERY sharp carbide end mill which is much harder and works better at higher temperatures, so chips fusing to the cutting edge isn't as big a problem. Aluminum also undergoes a lot of thermal expansion-- virtually every soft metal you might work with loves to absorb heat, aluminum can get piping hot in a matter of seconds, so you have to manage heat via symmetrical machining, coolant, making sure your cutter is always super sharp and preferably very hard. But, if you're using HSS because it's all you got, the best recommendation or trick I can offer up is to spray a tiny little bit of WD-40 onto your part, or area that's being machined-- that, or keep it flooded with coolant. The aluminum won't gum up and it will cut like butter with WD-40 though. Give it a spin sometime. Works for drilling or sawing aluminum as well ;) Either way, awesome set up man.

Ответить

I would love to get a machine like this. I’m going to try and convince my boss to get one haha. Can’t wait to see what you do with it.

Ответить

do yourself a favor and spray wd-40 on the tool also. you will love the new finish.

Ответить

$5k for tiny cnc, lol. what a joke.

Ответить

Thanks for posting this video, none of the other reviews really do much other than the included demos. I've been trying to figure out if this can cut Al on the 4th axis; you answered that in the first seconds of the video. You then went on to discuss possibilities that I hadn't even considered. How has reliability and maintenance been?

Ответить

worst this have size, totally too small, only PCB or jewel and figure maker need small, good have flexiple, cnc,laser, and tool changer, very bad have price ower high super expensive.

Ответить

5000 $ can build totally better and biggest machine DIY at garage, lot lot biggest and strongest machine. because good about size 1000x1000x300 work area machine cost less than 1000$ nema 23 motor linuxcnc cnc, and Vcarve and fusion softwares free. same 4000-5000 $ cost onefinity cnc but DIY can make similar but lot better parts less than 1500$ nema 34 or servo motor cnc. lot more strong and accurate.

Ответить

Im a CNC Machinist and working daily on Hermle Machines.

You did a pretty good job and i would love to have this at home!

Looks very nice

Calipers for measuring inner circles are just not accurate. Your .1 was 100% wrong measuring tool, not the machine. Hole gauge would be a little more accurate. I've run into this measuring problem myself before I figured out my mistake and literally did that DiCaprio pointing at the TV meme when I saw you do it too lol.

Ответить

Producing crap for a lot of money, this is what happens when people have more money then brains

Ответить

You should mention that you have to re insert the removed parts of the chuck in the same spot. Otherwise you can get higher runout. Normally the parts of the chuck have marks and the chuck has corresponding marks.

Ответить

Nice Bell clapper!

Ответить

Clean passes are better with down milling.

Ответить

Good job!

Ответить

I have no experience with this machine, nor do I intend to buy one, but the simple fact that they chose linear rails over linear rods puts it miles ahead of at least half of the other machines in this class.

Ответить

The best cnc machine is, what you did build by yourself! Is will do better job and you can learn a lot during the building process. If you can use a cnc machine then you can build it too. Don't waste your money!

Ответить

Did you buy the machine or did they give it to you?

Ответить