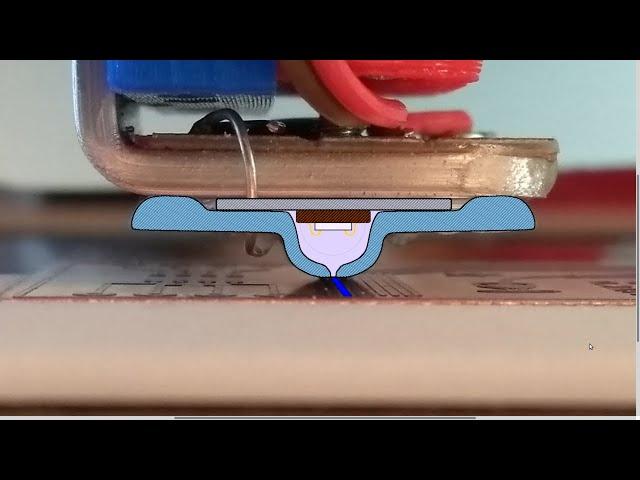

Make a PCB with 3D printer, UV led and photosensitive film

Комментарии:

Good stuff 👍🏼

Ответить

Great keep it up ❤

Ответить

very very compliment , all fantastic

Ответить

genius.... brawo

Ответить

8 thou track pitch isn't bad at all.

Ответить

Fantástico

Ответить

Interesting way to sensitize PCB photoresit, what kind of PCB trace resolution can be obtained? Good enough for QFN/FPGA circuits?

Ответить

Это было бы интересней если делать детали из лака уф тогда бы был бы толк

Ответить

Помоему проще фрезой Сразу сделать плату чем печатать и потом травить...😅

Ответить

This is pretty neat. What about - instead of making a pinhole with an LED inside - mounting the LED somewhere out of the way and coupling it into a TOSLINK cable to not only position light output more precisely but also reduce the complexity of the setup?

Ответить

I've been doing something similar using a resin 3D printer, much easier. Just create a single layer print with the reversed circuit design, and expose it for 40 odd seconds directly on the printer screen.

Ответить

Гениальное просто

Ответить

Interesting technology! Thank you!

Ответить

¿Y usar laser de grabado? Con pintura de cualquier tipo sobre el cobre

Ответить

I had such project in mind however later gave up and just used SLA printer display for exposing photosensitive film on small (~10x15cm) boards.

Ответить

хороший индийский акцент

Ответить

Wow! That is an amazing system.

Ответить

Man, you are the Bob Ross of Electronic.

Ответить

Thank you so much! Shared in Hungary :)

Ответить

Brilliant, just brilliant. I look forward to additional instructional videos.

Ответить

Hello, your work is very nice ,I will do it when I have the opportunity and time :S .after getting out of jail XD ... I wanted to try to make eye lens for imaging by pressing a matrix on a transparent led surface like yours on a simple level.even pcb circuit, battery, mechanic, synthetic, texture, metal, plastic, wood :) was a nice .When you think about it, it is possible to print full brain tissue, even positronic brain XD there are a few more things i want to try.

Ответить

How it would work with laser cutter?

Ответить

nicely done Will, maybe an old mechanical watch movement can help you to make the orifice. I would use a jewel of it. vary of sizes are to find. balance axel is usually between 0.09 to 0.12mm, they are wear-resistant. Hence, this is how they made the pcb films long ago with the use of aperture wheels. If I find some time will make a similar device and upload a video of it. " just did a quick test, the red ruby doesn't filter the UV light"

Ответить

how do I contact u?

Ответить

With less effort could add spindle = turn into cnc and route board, no need for nasty chemicals and can drill holes with same machine :)

Ответить

please upload more video about this

Ответить

i am in

Ответить

Круто!

Ответить

I tried do almost this. First I tried print plastic to the plate, but nothing succeeded. Then I tried attach pencil to hot end and thought printer can drawing it, but I'm used gcode for 3d model and printer didn't pull up printhead when changing positions. This solution is amazing. I will try to repeat this.

Ответить

Leuk project, goed werk!

Ответить

what software do you used for desing pcb.

Ответить

I wonder if you can use a scrap piece of fiber optics and glue it in the hole as a makeshift lens. I would hesitate to use single mode as its way to small, but maybe? I think you would have to polish the fiber each use though as it would scratch itself up. Humm, maybe it doesn't have to drag itself on the surface, as its small enough. Ugh to to play with this setup, digging out my old ender 3 now and my 20 year old splicing kit hah.

Ответить

Woderful solution to make PCB boards on a 3d printer. Thanks

Does it make it in just one pass. Only controlling the time the led is lighting over a point?

Where you get the photosensitive film?

Ответить

Formidable ! 👍

Ответить

Amazing what people do with the humble Ender

Ответить

I never seen Subscribe Number increasing , that much Fast 🎉🎉

Ответить

I'm just wondering what the actual gain of this approach is. You still need to develop the UV-sensitive layer, so how is this better than printing out the mask on a laser-printer (on a transparent sheet) and using that to expose the UV-sensitive film? I would expect that the real gain would be to get rid of the exposing and subsequent etching/dissolving mess, no? Then again, I'm at the "soldering TH components on perf-board"-level, so all this is just way out of my league ...

Ответить

Impressive project. Just one small criticism: please don't pronounce LED as "lead" ;)

Ответить

I like this alternate usage very much, and believe that I will try it.

Ответить

I used UV laser instead. I was able to reliably get 0.25mm traces. I also tried adding a motor with a drill to make vias and mount holes. The only con with a laser is that it uses PWM driver and can’t be adjusted with input voltage (yet this is how most 3d printer controllers work - the gcode command adjusts voltage).

Ответить

Have you thought about a solution using a resin printer, finding a way to clamp the copper plate to the printer bed ? You might get a much greater resolution and precision

Ответить

I have three CNC machines, and a 3D printer... did I ever think of using it to expose photosensitive film? NOPE!

Great job! Thank you for many new ideas!

meglio usare un bromografo😊

Ответить

Buen video, espero con ansias más videos así

Ответить

I wonder if this can be done with some type of laser with very narrow beam... great project!

Ответить