Комментарии:

Andy is it the camera angle. The thickness you mentioned as 3mm that's just under an 1/8 of an inch your piece looks thicker?

Ответить

Very nicely done.

Ответить

Excellent build. I acquired a 1949 south bend heavy 10 a couple years ago and find myself getting involved in side quests of tools and attachments when working on a build. Approximately how many hours would you say it took for your roller build?

Ответить

woooww

Ответить

Thanks!

Ответить

Thank you!

Ответить

How much$ did it cost you to build?

Ответить

Nicely done sir.

Ответить

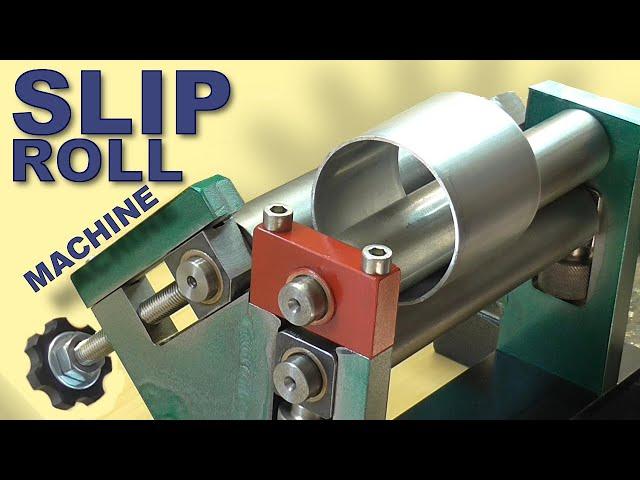

very, very nice setup. improved Vincent R Gingery model, in difference that top roller is almost fixed in this version (one side is used to pool out finished cylinder, while Vincent takes off his top roller completely).

only thing that I will improve is 2 or 3 sets of gears, one for small thickness, second one for range 1mm to 3mm and third one for 3mm-5mm, so no needs to stress teeths with longer distance. changing a gears is simple, as I see, just align them with a key.

I like it very much, will try to contact some who has knowledge of this matter and ask to help me develop same thing, just 300mm long rollers and with 3 sets of gears.

Tnx for your video and free drawings,

Cheers.

Hi Andy can be able to mound a motoer with selector speed please

Ответить

Question; why 45 degree angle for the adjustable roller? Thanks for a great vid.

Ответить

How I can get dimensional drawings on net ?

Ответить

Bạn cho mình xin bản vẽ thiết kế chi tiết nhé. Thank

Ответить

Patience is something you have an overabundance of.

Ответить

Nice video.. Thanks..

Ответить

Nice one. Thanks for sharing!!

Ответить

Fascinating thanks 👍🏼👍🏼👍🏼

Ответить

Thank you from Brazil!!!

Ответить

That's pretty cool. I haven't seen a reciprocating saw in quite some time. Oh and nice project and work by the way :)

Ответить

Just wondering, why do you cut the initial shapes with a hacksaw? Less material waste/more control?

Ответить

Yeah, I was just looking for a simple slip roll build, I don't have a lathe.

Ответить

Rather than a longer handle, how about a 70mm(ISH) gear where the handle is now, geared to another 28mm the handle is attached to?

Ответить

Very nice work. I'm about to make a bigger version. I'm planning to use 30mm GE30C spherical bearings. Has something like this been tried before?

Ответить

Making something that makes a prefect circle out of metal cannot be underestimated. Well done.

Ответить

You are a talented machinist and fabricator. Fusion 360 really changed the game for home/ hobby makers.

Ответить

Think you could use a portaband 👍

Ответить

Fabulous job, thanks for sharing.

Ответить

You can set the 3mm sheet on an electric cooktop for a few minutes. Move it around so the heat is distributed evenly. Drop the sheet on the floor. It will not ring like a cold piece of aluminum. It will make a sound like a piece of oak being dropped on the floor. It will form and roll through the roller with ease. Aluminum will after heating will be workable for a few minutes. It should be long enough for your roller. I press parts in a 5 ton press using the same process. Old ziplock bags between the parts in the press help the aluminum go where it's needed when forming parts. Have a great day.

Ответить

Wish i tooked the machinist subject in school 😕

So I could have never ending projects ahead to kill my time

Nice but can it do steel or only aluminum

Ответить

Mount that roller on a nice solid bench and it would be just fine; and very much easier to crank. You're losing a great deal of torque in that flimsey mount.

Good job!

Powered would be nice....

Save your arm for liftin pints... 😂

😎👍☘️🍺

Only found your channel a couple of days ago and must have watched 1/2 of your videos already. I'm looking for some projects and this one looks a good one. I'd have put the handle on the bottom roller so it rotates the "right" way. Nice to see that its a channel done by a fellow Brit. Love the Aboms, Oxtools and Stefan etc, but really nice to see such a nicely filmed and set channel from a UK maker.

Ответить

Nice project. Did you consider replacing the gears with a Schmidt coupling? A Schmidt coupling can transmit the rotation over a wide range of different spacings between the rollers and is pretty easy to make compared to involute gears.

Ответить

Big respect. I own a multi-M$ manufacturing company with all kinds of crazy cool capabilities. Makers like you impress me to no end.

Ответить

a couple of shaft collars on the outfeed roller would help keep the thick stuff straight. I am definitely building one, thanks so much Andy! I will use it to roll the front structural components of a miniature airstream trailer/ single person camper for ebike.

Ответить

Félicitations très beau travail. On est mieux servie que par soit même merci beaucoup . Continuer de nous régale avec vos formidable vidéo

Ответить

Subscriber

Ответить

I am inspired by your video.

Well done man!

Great job. Also very professional graphics etc.

Ответить

Excelent !!!

Ответить

Outstanding, you have earnt another subscriber, thank you for the free drawings, it is much appreciated.

Ответить

For me, the combination of machining and tool making is a winner. You show just enough to demonstrate the process, which is great. Better than making the viewer feel like they've put in a day's work.

Ответить

It is the best slip roller in the world.

Ответить

Very nice job!

Thought about such thing and even made some drawings, but the project was stopped.

I'll use your ideas for it. Thanks!

Would it be possible to make detachable gears with some sort of locking pin or something to resolve the gear meshing issue at larger thicknesses?

Ответить

.. A superb build ,..

Ответить

Really enjoyed your project. Thanks so much for your time and effort.

Ответить

Have you tried rolling a cone?

I'm a bit perplexed by the load ratings of oilite bearings. Being plain bearing i would think they would have higher load ratings than for example a needle bearing, but they dont.

![[FREE] #NPK #SinSquad MLoose x LR x Tugga x UK Drill Type beat @lilsosaprod_ x @J13K [FREE] #NPK #SinSquad MLoose x LR x Tugga x UK Drill Type beat @lilsosaprod_ x @J13K](https://invideo.cc/img/upload/SXZFT2RyTU1mWjE.jpg)