Комментарии:

Love the channel.

Ответить

You need to be a wood worker to be a metal shaper lol

Ответить

Outstanding!

Ответить

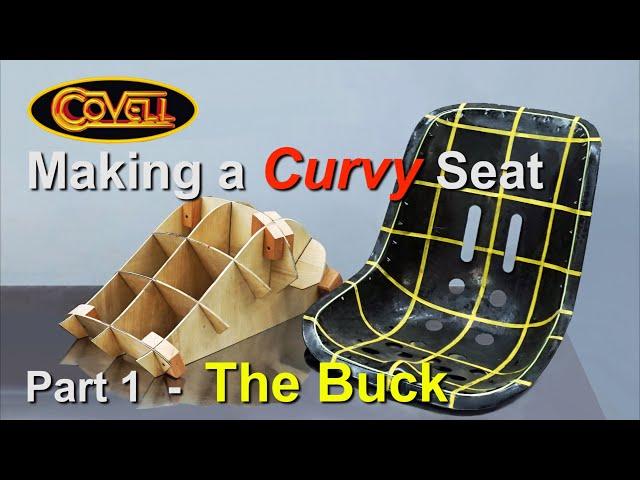

A fascinating insight and demonstration into producing reverse templates and formers for a contoured seat profile. The simplicity of your methods to replicate the complex geometry were wonderful to watch and learn from. Such ideas and techniques are applicable to other crafts. Many thanks for sharing this video - your skill, attention to detail and clear presentation is most appreciated!!!

Ответить

The way those cross stations looked when stacked reminded me of boat hull drawings. You get two grids, one is side view, one is split in half for front/back. Sometimes there would be a split top/bottom view as well. Each grid has outlines of hull cross-section at predetermined points. That made it really easy to copy the shape of the hull for model making and such. And because they were on a grid, you could scale it to anything and basically eyeball each 'station' from there. Grids made it way easier than trying to copy/size it all free-handed.

Ответить

👍👍👍👍👍👍

Ответить

Mr Rogers, Papa Smurf and Chip Foose walk into a bar..... surprise Ron Covell is bartending with the greatest patience and comforting voice haha. In all seriousness this man is incredible! Love these videos

Ответить

Another faultless demonstrate. Thanks for posting.

Ответить

How do you determine the position of the matching holes you put into the long stations?

Ответить

Nice work Ron, would you be interested in making a video on making metal wire rings like what you made for your alignment pins?

Ответить

Greg Buscher, make that the World!!!

Ответить

Another wondeful incredible video. Thanks a lot for share your skill

Ответить

I have a question for you Ron, in Europe we can't get 3003 Aluminum which I used when I was in the US. We can get 5083, 5086, 5754, 1050 and others that are irrelevant for metal shapping, I need to build the whole front of a curvy 50's race car. I am on the fence between 5754 and 1050, I'm kind of scared that the 1050 will be too soft for the body panels, but I talked to a metal shapper that uses it, the 2 others I talked to use whatever is available at the moment of their supply run at their supplier, so I guess 5754. Which one would you recommand?

Ответить

Merci

Ответить

Do you know when you will do the build video for this seat,

Ответить

We're honoured to see how it's done, a mystery well explained!

Ответить

Knowing that is a great way to make such a seat, seeing it actually built makes it all that much more interesting and easier to understand. Techniques is everything. Thumbs Up!

Ответить

Looking forward to seeing how this project turns out! Super video as always.

Ответить

As this video concluded, I said to myself:

"The buck stops here."

Then, I thought: " OMG! I'm making jokes that sound like my dad.

The metal doctor

Ответить

Applied topology, practical excellence! Thanks for the lesson.

Ответить

Great content but I do believe you skipped over the difficult step of getting the correct angle for each cross station onto the center longitudinal station.

Ответить

Thank you for this inspiring video and for all tips and tricks I really enjoying it

Ответить

NEXT VIDEOOOOO!!!

Ответить

Ron, thank you so much for passing on your plethora of knowledge. I learned so much from watching his videos. Little things like using the compass to draw an offset line to make the pattern is so simple but genius.

Ответить

Cant wait for the metal shaping!

Ответить

Thank you for the knowledge!

Ответить

Hi ron would it be possible to a video on the actual making of the seat from the buck. thanks

Ответить

How on earth did I miss this ,, looking forwards to seeing it , even though Ive watched your bomber seat build many times .

Ответить

Always a pleasure watching your instructional videos, Sir!

Ответить

sweet job

Ответить

You have a true gift for making complex things very simple. I'm not sure I'll ever make a bomber seat but at some point I'll make something from what I learned in this video!

Ответить

I knew it!!! (No 3D scanner in his shop) lol.

Ответить

Another great tutorial Ron!

Ответить

Awesome video!

Ответить

You’re the Mr. Rogers of metal shaping. After I watched your first bomber seat and researching them I saw the Porsche seat and I was wanting one. I might try this.

Ответить

Amazing work, and you even gave us the templates.

Although, knowing the corporate landscape, could this land you in hot water if Porche has a patent on those seat dimensions and/or shape?

Or is it fine as long as your not making them for profit?

thanks for the great video Ron and for making the templates available. i will download a copy and try to make one myself. cheers.

Ответить

Awesome!

Ответить

15 minutes of fabrication bliss😊 It's sort of... ironic? appropriate? reversal that when XCor was developing their Lynx sub-orbital spacecraft, they used Kirkey aluminum race seats, derived from bomber seats.

Ответить

Magnificent. Your granular approach, small step by small step gradually unravels the mysteries of the job. Similar to a chess game in space, seeing you at work is so rewarding. I'm sure you inspire a lot of people. Thanks for your videos.

Ответить

Late to watching this video which IMO was good as I spent almost as much viewing time as I did reading your responses to comments, lots of info there, thank you for your time/mentoring

Ответить

How do you form the metal over the buck? I am wanting to make a "banana" seat for a bicycle. Hoping for a part 2 video covering the metal forming work.

Ответить

Did you just eyeball the angle for the center seat notch on the long patterns?

Ответить

We’re can I buy some of the thin chipboard you use please

Ответить