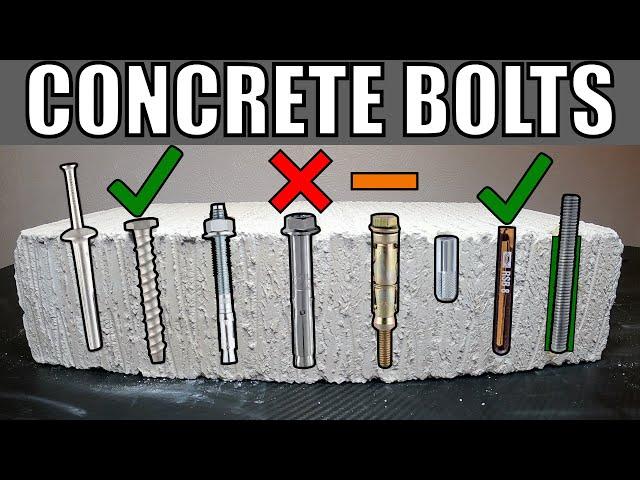

CONCRETE ANCHORS FIXINGS AND BOLTS - 8 DIFFERENT METHODS FOR FIXING INTO CONCRETE

Комментарии:

Thank you!!

Ответить

Brilliant video super helpful and we'll explained!

Ответить

Love your style of teaching and illustrating.

Ответить

the anchorbolts i have are loose at the end,you can screw off the expansion bit. isnt it possible that this part will not grip in the brick ?

Ответить

You have more important things to worry about like your entire society collapsing. The UK has fallen.

Ответить

Terrific explanation and demonstration. Thank you so much!

Ответить

This is probably one of the best demonstration videos I’ve ever came across, clear, no nonsence, straight to the point, well done sir

Ответить

Fantastic video mate, thanks!

Ответить

My Favorite is sleeve. They never fail on installation.

Ответить

Need more videos like this. Clear and to the point, excellent visuals, and shows multiple types of anchors and how to use them

Ответить

Missed opportunity to make money was not putting in links to the different bolts and drills. I know I would have bought through a direct link.

Ответить

AnkaScrews/screwbolts every single time, with the exception of a chemical anchor for extremely high loads. When done properly screwbolts will hold many hundreds of kilos, the clamping force means they'll never loosen, and if you need to remove them you can easily backfill. Come in every possible size you could want. Screwbolts are also much more preferable for install close to edges, close to other anchors, and in bricks where expansion/sleeve anchors like a Dynabolt will have an much much higher chance of cracking or splitting the substrate.

Ответить

Fab video, i appreciate the amount of prep that must have required :-) i'm attaching my timber ground beam for an outhouse to solid concrete block piers and i think ill use the second concrete bolt shown

Ответить

This rules, you rock

Ответить

Will the concrete scew work in Brick? would resin help?

Ответить

Is that England accent?

Ответить

my bolt is spinning with the nut. it wont lock.

Ответить

Load test would have been nicer. As most of us know already how these work without your cutout view.

Ответить

This was great! Thanks for making this video!

Ответить

Good video straight to the point no messing brill

Ответить

Nice job on the visuals! Keep up the great work, maybe other types of screw/bolts, nails, or tools. Thanks.

Ответить

are you jocking?

Ответить

I think it's worth noting that when there is a higher density to the concrete/cement the standard impact becomes less and less efficient and the rotary hammer more and more necessary.

Ответить

These are all water- and weatherproof methods, right? I plan to build a pull-up bar with wooden beams on a concrete base.

Ответить

My personal fav is the concrete screw bolt. It holds firmly and can be removed and the hole filled.

Ответить

This doesn't look like concrete, the concrete I know is much harder, not so crumbly! My favorite anchor in real concrete is a brass anchor.

In softer concrete, a Chemical Anchor! I'm talking about maximum durability here, if you need something simple to hang on the wall, then almost anything will do!

Thanks for sharing which Bolts would be best for securing a Gun Cabinet I think our wall is Breeze Block as it’s an old House.

Ответить

Resin not the capsules are strong

Ответить

I've chosen concrete bolts for myself as a perfect solution to use in the rented apartments, where you have to remove all your fasteners and fill the holes in the walls when you're leaving it.

Also they are reusable to some point.

Just dont drill brick/concrete with a combi, don't! Their for weeks you'd be

Ответить

when installing car lifts we use 3/4" (19mm) sleeve anchors 4 per post straight into the floor. we also use some epoxy with the sleeve anchor not for more strength but to make the holes waterproof, if water gets into your holes and you live where in can freeze the freezing water can damage the concrete.

Ответить

👍

Ответить

You can remove an expanding bolt fixing. Remove the nut. Hammer the threaded part down a bit and pull the sleeve out. The expanded part will bend back in.

Ответить

What about a Fisher wall ankor.? DUEBEL

Ответить

Well done, thanks from Florida.

Ответить

Teşekkürler faydalı oldu

Ответить

I'm surprised the resin is the strongest.

Ответить

Great video

Ответить

Thanks. What I don't like about the hammer in type is that they can't draw what one is fixing to the concrete tightly. They are OK for shear loads.

Ответить

Drilling concrete overhead for 20mm anchors, with near on 500 holes you were always waiting for the near on wrist breaker when you side swiped the rebar.

Ответить

great video, I've used some of these before and I will be using a couple of the expansion methods in the next day or so. BUT I have a concern. I never drill into concrete without a dust mask and that is also very important when using shop air to blow out the dust in a new hole. I scrolled back into the comments to see if this concern had been mentioned before. I didn't see it! Considering many viewers will be novice DIY'ers I wanted to point this out... Don't breath concreted dust. Its dangerous to your health. thanks

Ответить

Excellent video. Well done

Ответить

can`t hear you very well !!!!

Ответить

Tapcon all the way

Ответить

My hog is 9 inches. Facts. But it's only 200 mm wide. Should I drill a really big hole for this? Help.

Ответить

The resins can be removed somehow or are permanent?

Ответить

Some drop in anchors are very short & some also have a lip. Anchors can also slip out when used in a overhead install or spin when tightened. The setting tool may also be unsuitable when the concrete , slab etc is under many layers as it won't reach the anchor.

.

Many SDS drills have a chisel feature. You can use a sds drill bit as a setting tool as long as it's a smaller diameter then the anchor being installed.

.

Eg.Use a 8 mm sds bit with your drill on it's chisel setting to gently hammer in a 10mm or 12mm drop in anchor.

.

Thanks for uploading.