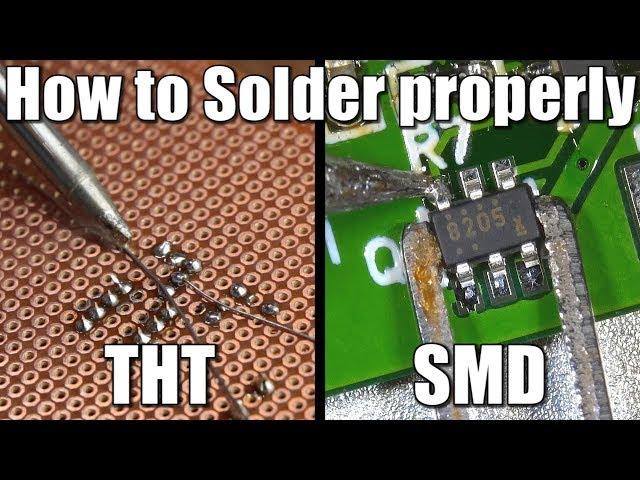

How to Solder properly || Through-hole (THT) & Surface-mount (SMD)

Previous video: https://youtu.be/69G522AeRq8

Facebook: https://www.facebook.com/greatscottlab

Twitter: https://twitter.com/GreatScottLab

Tools/Materials that I recommend (Affiliate Links):

Aliexpress:

Soldering Station: -

Solder (0.5mm): https://s.click.aliexpress.com/e/_dWS2USx

Solder Wick: https://s.click.aliexpress.com/e/_dZQqXqJ

Tweezers: https://s.click.aliexpress.com/e/_d6RmW7H

Microscope: https://s.click.aliexpress.com/e/_dUxuQgf

Flux Pen: https://s.click.aliexpress.com/e/_dYJSZnh

Hot Air Station: https://s.click.aliexpress.com/e/_d897Ru3

Solder Paste: https://s.click.aliexpress.com/e/_dYRUfDl

Amazon.de:

Soldering Station: http://amzn.to/2ezB5Vk

Solder (0.5mm): http://amzn.to/2euGKs4

Solder Wick: http://amzn.to/2vVO6eJ

Tweezers: http://amzn.to/2x2xKpB

Microscope: http://amzn.to/2ev9XTQ

Flux Pen: http://amzn.to/2eRsaeN

Hot Air Station: http://amzn.to/2ev7BnM

Solder Paste: http://amzn.to/2wyeCwi

Ebay:

Soldering Station: http://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_ff3=2&pub=5575101368&toolid=10001&campid=5337582279&customid=&icep_item=232228178227&ipn=psmain&icep_vectorid=229466&kwid=902099&mtid=824&kw=lg

Solder (0.5mm): http://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_ff3=2&pub=5575101368&toolid=10001&campid=5337582279&customid=&icep_item=310809071679&ipn=psmain&icep_vectorid=229466&kwid=902099&mtid=824&kw=lg

Solder Wick: http://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_ff3=2&pub=5575101368&toolid=10001&campid=5337582279&customid=&icep_item=171827508880&ipn=psmain&icep_vectorid=229466&kwid=902099&mtid=824&kw=lg

Tweezers: http://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_ff3=2&pub=5575101368&toolid=10001&campid=5337582279&customid=&icep_item=252601869448&ipn=psmain&icep_vectorid=229466&kwid=902099&mtid=824&kw=lg

Microscope: http://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_ff3=2&pub=5575101368&toolid=10001&campid=5337582279&customid=&icep_item=192284083946&ipn=psmain&icep_vectorid=229466&kwid=902099&mtid=824&kw=lg

Flux Pen: http://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_ff3=2&pub=5575101368&toolid=10001&campid=5337582279&customid=&icep_item=172740796011&ipn=psmain&icep_vectorid=229466&kwid=902099&mtid=824&kw=lg

Hot Air Station: http://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_ff3=2&pub=5575101368&toolid=10001&campid=5337582279&customid=&icep_item=322301372916&ipn=psmain&icep_vectorid=229466&kwid=902099&mtid=824&kw=lg

Solder Paste: http://rover.ebay.com/rover/1/711-53200-19255-0/1?icep_ff3=2&pub=5575101368&toolid=10001&campid=5337582279&customid=&icep_item=142328779024&ipn=psmain&icep_vectorid=229466&kwid=902099&mtid=824&kw=lg

In this video I will show you my technique when it comes to THT and SMD soldering tasks.I show you with some practical examples how easy it is to solder and what kind of tools and materials are necessary to do the job.

Music:

2011 Lookalike by Bartlebeats

Killing Time, Kevin MacLeod

(incompetech.com)

Тэги:

#solder #soldering #guide #tutorial #how #to #beginner #beginners #explain #through #hole #through-hole #THT #technology #SMD #SMT #surface #mount #device #surface-mount #material #tool #tools #technique #wick #desoldering #desolder #microscope #package #TQFP #QPF #QFN #SOT #DIP #electronics #greatscott #greatscott! #easy #iron #screwdriver #conical #tipКомментарии:

SMD OR GET OUT!

Ответить

Thank you for help I was really interested in this...

Ответить

@GreatScott! Was all the microscope soldering footage filmed through the Andonstar ADSM201 microscope?

It looks really clear and not too expensive.

The one I cannot get is the little Pchs boards that have half circles you have to solder to and pads. They come in Chinese kits. They never have good connections. Ask I supposed to add something else?

Ответить

It's harder than it looks though

Ответить

I just want to ask. Why the solder didn't stick to PCB?

Ответить

THT soldering, minimum requirements:

a perf board with holes in it, copper eyelets

components you wish to arrange on the perf board

255 miles of solder, give or take the length of France for complex projects

Copper wick

Soldering Iron

The main disadvantage in hot air soldering is that we have to heat the component so the component itself can melt the solder I think this is how it should be

Ответить

You shouldn't be teaching people to SMD solder if this is your level of instruction you provide! The internet enables too many people to rant about crap they have no idea about, and get financial reward for it.

-Don't use conical tips. They are atrocious. They seem attractive at first glance, as they are pointy and have a fine "precise" tip. In reality this causes lack of contact surface area and in turn lower thermal transfer. Personally I like knife tips and beveled tips. I can solder 0201 and 0402 happily with a Hakko T12-B2 tip if need be. Go to is a FM2032 iron with a KU tip on it.

-Learn to use liquid flux!

-On lots of your joints, there is a hefty excess of solder.

For anyone wanting to actually learn to do any of this properly, look at Louis Rossmann's videos doing computer motherboard repairs. They are worth watching. He actually knows what the hell he is talking about.

Great video sir! Thank you.

Ответить

Lower temp solder paste. And a hot air rework station. NO REASON to use an f'ing soldering iron anymore. I hate how primitive using a soldering iron is. Reflow is a BLESSING.

Ответить

thanks man

Ответить

SMD components are simple once you get the hang of it. I lost the coordination on one side when i had a stroke, and I still manage

Ответить

thanks a lot!! Me and my gay partner love your content😍... slay daddy

Ответить

Practice is everything...totally correct. I learned since last year soldering and i must say, it is (depends on the situation) relatively easy. And i like to solder.

Ответить

This is not what I was looking when searching “how to SMD”

Ответить

conical tips suck

Ответить

I'm gonna cry because newbie me and and my groupmates did it very wrong when doing it with the pbc, instead doing it like placing the solder to the board, we connected each "dip" to a wire the solder and we didnt even have a socket to protect the IC so it dosent work and it was driving me crazy, so now im doing it by myself

Ответить

I have trouble getting the tin melting. If not that getting the tin to stick to the board. Why can't i find some truth about how to get it to stuck. You show few sec in and out. Nothing happens here. It can melt but no easy fast flow.

Ответить

This is great info for us newbs. I also struggle with shakey hands, but I am damn well going to learn how to solder smd's.

Ответить

hi

Ответить

SMD can SMD

Ответить

Thank you for helping beginners with soldering. But as a professional, there is so much wrong in your technics. Your solderings wouldn t stand IPC 610 A Class 1 standard. There is no need for fancy equipment. Its all about handling and technics. For excample. No ESD Protection. No touching parts to solder by hand to prevent oxides and body fat getting on part or soldering pad. You need much less tin. Max allowed is a 90 deg angle. When double sided board, importance of filling the via min. 75 percent to the top. No tin touching partbodys. Resolder iron tip before putting away. Clean and retin before every soldering point. Talk about time/heat situation. No front. But I believe it is important to talk about this. Soldering is not glueing parts in place. I have seen guys, soldering the first time, builing kits for electronical launch systems for fireworks. Fake parts, because cheaper and sooo bad and dangerous soldering.

Ответить

For majority of pins you use EXCESSIVELY huge amount of solder. It not only makes the job look uglier - it makes soldering less reliable.

Ответить

I can't see why you'd intentionally bridge connections and then go over it with solder wick, when you can just do the job correctly the first time.

Ответить

The only thing you need to know about soldiering is "Use flux!" With a good flux and enough of it, even a monkey can solder. Without any, too little, or a poor one, even experts will fail. Beginners often are told, the reason why it didn't work well is that their solder iron wasn't hot enough, they didn't apply it long enough to the board/component, they used the wrong solder or their equipment is cheap crap; but all of that is rarely ever the case, as the same person with the same technique and equipment will get brilliant results as soon as they use a decent flux. People also think they may not need flux when they buy a solder that already contains a flux component but that's not true. The flux in the solder is there so you don't have to constantly apply flux on your solder iron when melting the solder but that flux is basically gone once you melted the solder on the tip of your iron. To apply the melted solder to a board or component from there requires additional flux at the board/component.

And also don't fall for the "you need solder containing lead as only that has a low melting point". Sn10Pb88Ag2 contains 88% lead and melts at 290 °C, Sn96.5Ag3.0Cu0.5 contains no lead at all and melts at 219 °C. Sure, Sn60Pb40 melts at 191 °C, which is a bit lower but those 28 degree really don't matter at all. You simply don't want to deal with poison lead if you don't have to. And if you really need very low melting solder, e.g. to desolder something that otherwise refuses to melt, use Sn42Bi58, which also contains no lead and melts at 138 °C, which is lower than any solder containing lead on the regular market (the best you can usually get there with lead is Sn43Pb43Bi14 and that melts at 163 °C)

🖤🖤🖤🖤

Ответить

It's a bit ironic that back in the days when my eyesight was good enough for the SMD soldering, all we had were tubes and large components. These days, my old eyes do not like the SMDs and I would much prefer the way we did things 50 years ago...

Ответить

BGA > did you go over BGA???

Ответить

wow~ it was so butiful how you did everything, soo~ coo~

Ответить

Should be able to rake solder TQFP with that amount of flux and less solder on the tip of the iron.

Just rake it past the pins steadily, the flux pretty much ensures that the solder will flow to the pins and nowhere else. First time I ever did it was soldering on an N64 and it was successful. Fast and less steps, cleanup can be a hassle if leads bridge, but looks like you've got fixing that down to an art form.

I worked in a manufacturing facility (Circuit boards and wiring harnesses)and also did commercial stained glass...in all cases an external Flux was required to be used ...ALONG WITH flux core you should use an external flux to get the best results...let me tell you we HAD to do this just to get the bond strong enough to pass quality control...the bonds fail EASILY with just flux core solder...TRUTH that cannot be stressed enough, just the core solder is NOT enough flux to get a truly strong bond... you have to use paste or liquid flux (pre tin wires to be connected and you would be shocked at how little solder you have to use to get an extraordinarily strong bond....also I pre tin the components to be installed WHEN I CAN...when they are too small just use flux paste or something like) (Just so you know, my father taught me when I was a kid and I got good enough that I was the guy on the line that did rework with the high temp soldering iron..it was actually a stained glass iron so I could super heat parts quickly to get them out...this was important to get a lot of heat into the solder joint BUT NOT THE PART...the longer you had to hold the iron the more likely it was you would destroy the part...so quick touch and remove the part ...ESPECIALLY when you were removing 16 pin micro chips connectors and the like(spend too much time getting that much solder melted and watch the part melt to hell...NOT GOOD...had to be LIGHTNING FAST so we used the 1200 watt irons...hard to find, even harder to use with skill, took awhile to get there but you had to be the best on the line to get the job)

Ответить

solder lines ??? come on, man. Using simply solder instead of a jumper wire or copper for tracks is just a big NO NO!

Ответить

Danke schön! Ich lernte schon so viel von dir und werde hoffentlich mehr Unterschtützung senden, wenn ich kann.

Ответить

Your accent is kinda like german are you from Germany?

Ответить

can you make a video of making pcb? i sow many pcb tutorials but non of them was good and i think you can explain that really good like you did in this video.

thank!

Does a solder paste work for, say a dsi power board connector? Kinda want to know as I broke mine and want to fix it.

Ответить

GreatScott, Thank you so much for everything you do for the electronics enthusiast! I really appreciate your efforts and I have learned a lot from your videos. Love your style. Salome my brother!!

Ответить

Chip quik (low melting point solder) for QFPs is a life saver

Ответить

Ight time to solder for the first time. Wish me luck boys

Ответить

how do i avoid brown marks burn on smd are they cleanable?

Ответить

![[FREE] HARDSTYLE x 90s TECHNO x GABBER RAVE TYPE BEAT - "cow" (prod. plucksunset) [FREE] HARDSTYLE x 90s TECHNO x GABBER RAVE TYPE BEAT - "cow" (prod. plucksunset)](https://invideo.cc/img/upload/d3NraDhPVlhwcVU.jpg)

![[FREE] Money Man Type Beat 2024 - "Bout Time" [FREE] Money Man Type Beat 2024 - "Bout Time"](https://invideo.cc/img/upload/OFlxNUFNWXJSYkc.jpg)