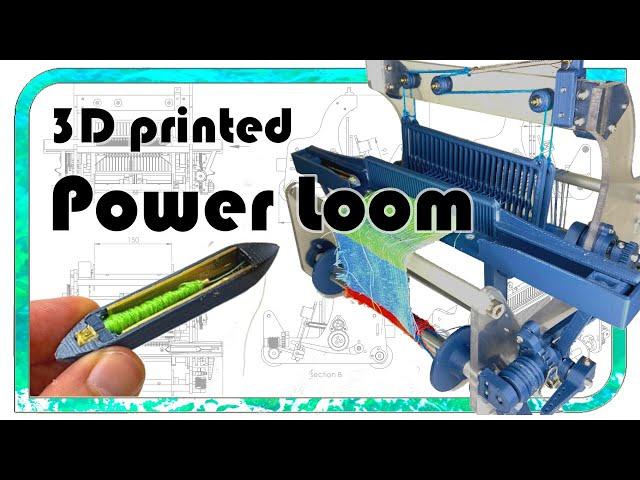

3D printed Weaving Power Loom / technical details, how it works, construction

Комментарии:

Hello. How to buy one?

Ответить

super cool

although the product is super loose

still super cool tho

Brilliant.

Ответить

How to buy this loom

Ответить

what an epic project. just an amazing amount of effort. super impressed with the engineering and constantly amazed at what clever people can do with an imagination and a 3D printer.

Ответить

Wow! So fun!

Ответить

Good job! The Meccano community including myself has built many looms like this. Most amazing of all is the Meccano Jacquard Loom built by Stanley Coates in 1938.

Ответить

I need the dimensions to make one

Ответить

nice but acrylic glass file?

Ответить

how can we get it , are you willing to sell?

Ответить

This is brilliant! - I am hoping to start a new job within a weaving mill soon, never done it before - so i am swatting up and stumbled across this vid - Gave me real insight to how the machine works, Thanks very much - helped a lot!

Ответить

I am an engineer and I have been trying for a long time in the field of making power loom machine, this video helped me a lot.

Ответить

Good job I fined model for DIY fishing net machine if you have any information about this

Ответить

Can u share the 3 d model

Ответить

How did you make the shaft?

Ответить

This is so so cool, Fraens! Great job! I'm currently working on a similar project at school, and would love if you could review our design. If you're willing to setup a meeting, what's the best way to reach out to you? Thank you, and great work again.

Ответить

Can I just print the frame instead of using acrylic? Would you happen to have files for it?

Ответить

M'agradaria connectar en privat amb tu per comentar alguns detalls del teu teler. Gràcies!

Ответить

Amazing work man

Ответить

Dude, this is REALLY cool. How long did took you to design this? I am currently working on similar project to this, I am greatly inspired by your amazing work.

Ответить

Can you give me the size and measurements of each piece for this machine please don't let me down

Ответить

Hi Fraens! Do you have an email contact? I am a final year industrial engineering student from Chile and I'd like to ask you some questions related to feasibility and costs production of a similar machine, and in the best scenario maybe you could build it. Greetings! Saludos!

Ответить

YOUR going to make some traditional ethnic weaver girl very happy. THIS is so F-ing sweet! ( for Finnish)

Ответить

Incrível! Parabéns!

Ответить

It seems that it is the shuttle that is causing the most trouble. Have you considered using a rapier weft insertion mechanism instead? I think that a band for a flexible rapier (takes much less space than rigid one) could be made out of laser cut polypropylen sheeting, and the drive wheel could be 3d printed. With a single sided flexible rapier mechanism the surplus band can just stay at the low side of the slay when retracted.

Ответить

Very nicely made! Impressive to sync everything mechanically from a single motor.

Ответить

Very good very good more weaving shuttle change control sensor video explain to us

Ответить

Good job. Do you have a model for the elastic tape weaving machine

Ответить

Very Goog next video weaving shuttle change sensor video explande tankiyou

Ответить

Amharic Translationdes

Ответить

When are you going into production? I want one, even if it's in kit form. (Lots of us who don't have access to a 3D printer or knowledge how to use it).

Ответить

Waaoo 😮🤗🤗

Ответить

Sir can I have the model file of the side board, u showed the dimensional PDF, but the dimension and location of the holes is missing.

Ответить

incredible😳😳

Ответить

Συγχαρητήρια.

Παρά πολύ αραιό.

Ε αν υπάρχουν σκιάδια

Θα χαρώ πολύ.

Ευχαριστώ

Your design and execution is great. I love it.

For improved clamping onto your shafts with 3D printed parts you can increase the diameter, hollow even or use hexagonal shafts. Using a small insert that fits into bearings would allow you to use hexagonal stock with no machining.

This is fantastic, OK the edges aren't much chop, and there were other issues, but the concept is great, and it seems to be relatively quiet. I hope you keep going with your project and that it was a fun project to do, thank you for sharing your video.

Ответить

Congratulations! Where do you learn to do this?

Ответить

A lot of thanks for this video

Ответить

it looks great! Your job gave us a lot of inspiration, we will follow your instruction and try to build a new weaving loom!

Ответить

Bro can you make package sealing machine 3d printed model.

Ответить

Hi buddy. I'm your new subscriber. This video is excellent i like it . Keep it up.

Ответить

weaver dobby harness printd video explain

Ответить

Very goog

Ответить

Can u help me ??? Please

Ответить

Can you help me to make this

Ответить

У тебя и 3D принтер напечатанный на 3D принтере)))

Ответить