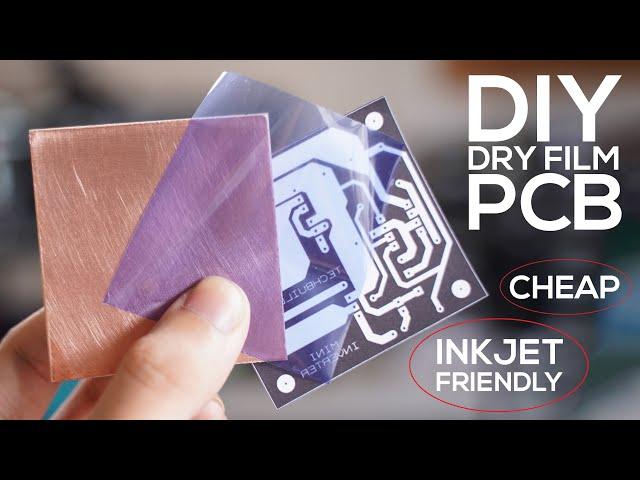

DIY PCB Fabrication (Dry Film Inkjet Method)

Комментарии:

DIY PCB Fabrication (Dry Film Inkjet Method)

TechBuilder

Latin Guitar Type Beat - "AZUL"

ENIGMA BEATS

The Mystical Villa Montezuma Mansion

BuzzFeed Unsolved Network

Mehpara Najafova - Columbus Day. Azerbaijani trailer

Мехпара Наджафова

Julio Sagreras. El colibrí. Interpreta: Nadia Borislova.

Nadia Borislova