Комментарии:

wspaniale robota wykonana znakomicie jestem pełen podziwu dla ciebie 👍👍

Ответить

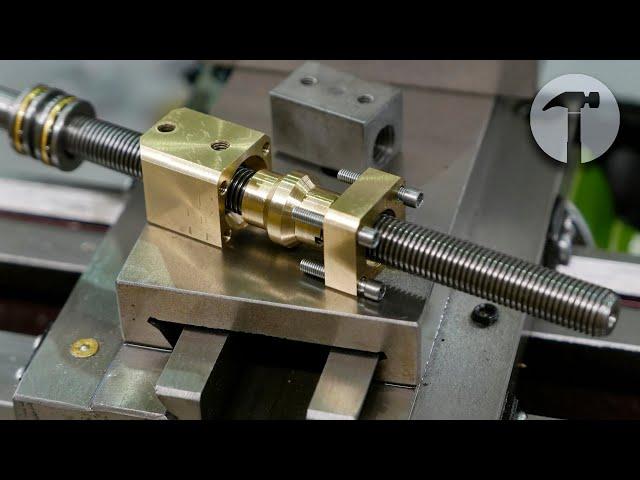

СУПЕР ГАЙКА или ЛЮФТ в 100ку

😜

i just dont get how you can stand looking at that horrid little degree scale stuck to the compound...

Ответить

Hai costruito un particolare troppo complicato

Ответить

Можно было просто купить настоящий станок и не изобретать его заново. Но если интересен сам процесс, то ничего не имею против.

Ответить

I can't begin to do precision work like the cuts you make. I have a cheap Jet lathe which has some kind of play which can make cutting tools dig in even on pretty small cuts.

Ответить

Hmm, kinda clever, 2 cutting wheels for extra rigidity.

Ответить

judging by the chips, you used brass, then this part will not last long, you had to use bronze.

Ответить

К сожалению, данная доработка неудачная. Неудобно регулировать. Есть решение лучше и проще.

Ответить

Turned out excellent.

I did a similar project to my Grizzly gunsmithing lathe about a decade ago. I simply bought a replacement nut and then cut it in half and inserted a spring of sufficient strength in between the two halves.

The spring was held sandwiched in between the two halves of my new lead-screw-nut by four long-enough screws in each corner of the lead-screw nut.

It too was adjustable but, my method was way harder to adjust than your design. I did it that way because I knew I could finish it in a day or less.

It worked well for me though. I just couldn't afford to have my lathe down for any length of time.

I’m a troll. Anyone want to argue with me for no reason… comment here please…🤔🧐

Ответить

Wonderful, veri nice Brainstorming, very good Job.

Ответить

Main take away here is how well you used what little you had, most people think you need machining equipment 100 times larger than what you have to make anything what we see you make in this video.

Ответить

You're a lathe master :)

Ответить

Петух твой орёт? Сам живой или за Зелю умер? Россия вперёд!!!🇸🇮🇸🇮🇸🇮🇸🇮🇸🇮🇸🇮 С уважением, береги себя, если жив, мы скоро освободим Вас от америкосов! С нами Бог!!!

Ответить

Well done, brilliant, better than mine, will copy, cheers

Ответить

lol, das SPIEL in der Spindel macht gar nix, jeder Dreher kann das bestätigen

Ответить

Uchwyt tokarki ewidentnie polski.

Ответить

And the wheel is still round.

Ответить

It’s people like you that make people like me, just like you. This is an awesome mod, specially for the Mini-lathe.

Though, I would think with a bit of measuring it can be modified to fit any lathe that needed this. Great job.

I think having minumum backlash is important especially on small machine or heavy cuts or turning square and etc.Would resist the tool getting pulled in especiallly your machine tool does not have sufficient gib lock or you are using that one axis for cutting.

Ответить

A great video showing lots of interesting techniques 😯 ( whether you want backlash reduced or not 🤞) K

Ответить

You could also have taken the existing spindle nut, drilled two holes axially for hard pins (3 mm?) and then cut the nut in half so that you have two short nuts. Mill off both parting surfaces at 5 degrees and make a wedge at 10 degrees with a hole in the middle that is several millimetres larger than the spindle. If you then make a thread on the slide between the two holes for fastening the threaded nut so that you can press on the wedge with a worm screw, you could also eliminate the thread play in this way.

Ответить

Здоров, земляк. Чёткие видосы. Отличная работа.

Ответить

47 dremel wheels later...

Ответить

Nice video shot, thanks for sharing it :)

Ответить

Good job👍👍

Ответить

Quedo muy bien la Tuerca Cuadrada, Medio Decimo y lo vas Registrando !!

Ответить

You have to fix everything from china

Ответить

rather than showing all the machining, a good drawing would be quicker and more helpful.

Ответить

How about using your words buddy. Are you deaf mute or something???

Ответить

Wow just fantastic workmanship

Ответить

Ten years ago I changed my minilathe to a brand new Chinese lathe with 255kg and 1,3 kw after I improved everything you could and It became a quite precise minilathe I sold it to a professional Vespa restaurator and he uses it to improve the cylinder and other parts of the italian motorbikes . I also changed the Nut into a sliced Nut with screws you could get the backlash down to a minimum...

Ответить

Like many here i absorb shit loads of shop & turning videos but I love lathe improvement, attachments, and upgrades the best. This project really shines because who the hell wouldn't love to reduce backlash to an absolute minimum? It's truly a rhetorical question. I'm going to investigate if I can adapt your excellent design to my old SB-H10 and Logan 920. Thanks for the very enjoyable and well done video. You did it with no monologue, yet the vid is clear enough to not suffer from its absence.

Thanks!

Wakodahatchee Chris

moral of the story DON'T buy a Chinese toy lathe save up and buy a bigboy lathe

Ответить

Crucial when you have a lot of brass to machine. Never tell anyone what you are doing, how big anything is, nor provide any guidance on speeds and feeds. A picture is worth many thousand words. Huh?

Ответить

Can I just toss this idea out there? Not trolling so don't take it this way! No matter how hard you try that lathe will never be accurate to anything of higher quality no matter how much time cash you drop into it lol. Just saying I own one! Not going to lie great video you did and such.Very nice clean job. But for all time and cash it would take to make this lathe other 90% that is off on it actually good quality lol could just buy better one for same price that all time and Parts to make new parts cost to upgrade the cheap crap one lol No upgrade required or hours of time lost fixing badly made parts. I know this piss people off even more but over time brass will chew up and backlash will return shortly. More it wares less on center with dials it becomes as well cause now worn opposing nuts are no longer correct pitch following the screw. Just saying ~ Not like I know anything anyhow

🍺😜👍

хорошая гайка👍 только вот если ещё масленку туда приспособить, то она будет жить и жить✌

Ответить

Ultimately the screw will wear more in the region of the most frequent travel and then you have to leave some backlash anyway, otherwise the screw will bind up at either end. You must still develop the habit of making the last adjustment of the cross slide against the reactive force of the tool pressure.

Ответить

I know you most hear this a lot, but you are fkn AWESOME!!!

Ответить

Bravo........a ball screw......cheers

Ответить

Very nice - and a wonderful example of how to use a lathe as a milling machine!

Ответить

It's about time someone came up with an answer to backlash.

Instead of just living with it or recutting new threads.

great job my friend

Ответить

How much would you charge me to

make this exact same thing? I’ll pay for the material, labor, and shipping up front friend….

О! Технарь нашелся )

Ответить

Interesante el video, me gusto.

Ответить

Do you sell these? i would love to buy one

Ответить