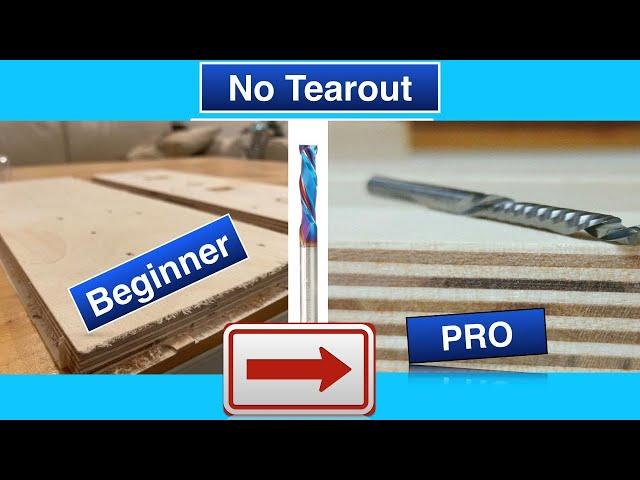

CNC Cutting Plywood CNC Router Beginner to Pro EP 04

Комментарии:

When I cut wood like that, I usually cut in mirror,and my first tool is almost always a 10° engraving bit with a 0.1mm offset. It's important to choose the cutting direction wisely. After this tool has cleared the initial path, I proceed to cut the interiors in a single step, while for the outer edges, I divide it into two steps. The first step with a 0.2mm offset, and finally, the last step to clean it all up. 😊😊😊"

Ответить

the most important thing is missing in this video FEED and SPEEDS for the tool that you recommended for beginners

Ответить

Thanks for the tips. Im looking to get more accurate on my cutting so i really found the setting of Z 0 information useful and will be picking up the gauge you show

Ответить

Love the content, keep it up

Ответить

Great video. Thank you.

Ответить

compression bits are good, but for deep pockets/slots there is a better solution. i cut it in two steps. at first i rut all contours with a down cut bit for about 1mm depth just to pass first layer of a plywood (to the middle of a second layer to prevent delamination). and after that i cut all remaining material with a regular up cut bit.

and for up cut i like to use 3 flute roughing (chipbreaker) end mills for aluminium. they are really fast )

Your work is great good sir,well received.Goodwill.

Ответить

Hello. Thanks for the informative content. It would be cool to see your considerations regarding cut quality x speeds and feeds.

Ответить

Great video! I have been using thin (1mm) basswood, as shim, to prevent the endmill from cutting into the base plate

Ответить

Putting these videos together in a series will make for a great library reference for all of us. Keep it coming and as always well done...

Also, I have never set my Z height off the spoilboard but your explanation as to why you prefer to do this was spot on!!! Thanks.

Great video, thanks!

Ответить

Thanks for the bit recommendation.

Ответить

No, the manufacturing industry standard is not to set Z0 underneath the part.

Sincerely,

Professionals Machinists Everywhere.

Great video! Thanks for sharing I have always been confused with measuring from the spoil board. Thanks for the explanation and tip!

Ответить

Some good tips but your cutting speed is waaaay to slow, good way to start a fire (yes I've seen machines catch fire from new users running those speeds), you should be up around 8m per min at a minimum with those rpm's.

Ответить

Thank you for your informative videos! I have quite some experience with CNC machining wood, but I always learn something new from your videos! :)

Ответить

True Baltic birch plywood is getting quite hard to find here in the US, in addition to being expensive.

And I am pleasantly surprised by the quality of some Shars stuff. I work with metal, and I recently used one of their parting tools with quite a large stickout of about 1.5" to part off a 3" (~75mm) diameter 8620 (low alloy) steel bar and it did not chatter or break off!

Great way to avoid hitting the spoil board all the time - thanks!

Ответить

Conventional cutting works best for birch plywood, it give the best finish is my experience. I normally cut it in 1 stroke, till 25mm thickness with a 10mm up/down cutter. (at around 12m/min). It's one of my favourite products to machine. Prices increased a lot in the last couple of years though.

Ответить

Some great tips. I often use .125" thick hardboard as a spacer, but with more experience the tape works fine. Not quite cutting all the way through is frustrating and messy to tidy up.

Ответить

I enjoy your content.

Ответить