Top WELDER Reveals the Secret to Perfect Welds FAST #stickweldingfabrication #weldingprocess

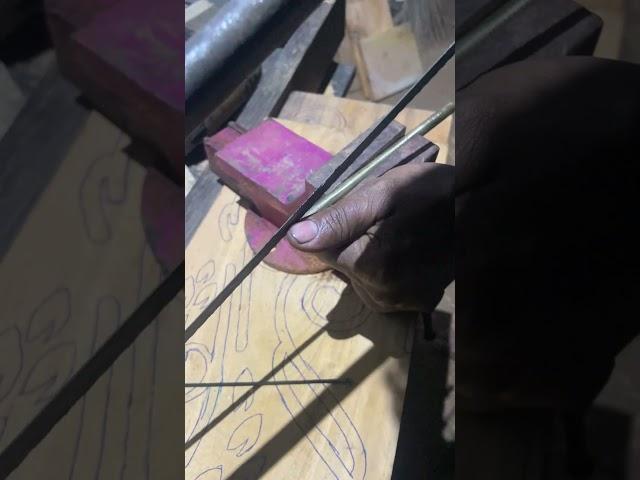

Learn how to grind your welded corners to perfection in 2 steps! There are many ways to grind welds down, but I've found this to be one of the fastest for square and clean corners.

Stainless steel weld seam laser cleaning. Laser cleaning is a great way of preparing surfaces for painting after welding.

Laser used in a video is a 100W machine.

P-Laser develops and produces low to high power laser cleaning equipment for manual and automated production environment. Our systems are made for industrial applications like:

rust removal

grease removel

paint removal

weld (pre) treatment

mould cleaning

how to weld,beginner welding project,how to grind a weld,how to finish a weld,finish metal project,grind metal,how to use an angle grinder,victograin,polivlies,grinding disc,grinding disc use,variable speed grinder,how to make,welding,diy,diy table,art,welding finish,grinding steel,grind stainless,polish steel,lincoln electric,m18 grinder,best grinder,how to finish steel,how to sand steel,metal project,beginner welding,first welding project,metal

yeti,ymco,yeti machine company,yeti machine co,gvllow,chopper,choppers,harley,harley davidson,harley sportster,harley davidson sportster,sportster chopper,motorcycles,how-to,how to build a chopper,sporty,harley chopper,sportster 1200,mechanic,chopper build,hardtail,hardtail chopper,bike shop,welding,hardtail frame,custom motorcycle,custom chopper,fabrication,chopper fabrication,metal fabrication,tig welding,silicon bronze,finish weld,metal finishing

SECRET on How-To Clean Up WELDS

#stainlesssteelwelding #stainlesssteelpolishing #ambroscustom

हिंदी में समझने क लिए कैप्शन हिन्दी में ON कर ले ।

Stainless Steel Grinding and Polishing on welded joints is an important task for any fabricator. And as I said its a time-consuming process to make joint up to high gloss finish. The perfect way to do this work is by increasing gradually the number of grit. Usually, a good buffing surface appears after 1200 to 1500 grit. But unfortunately, I am not able to find those grit sizes from the local supplier. But by giving slightly more time to the 600 grit scotch Brite wheel almost near the perfect buffed surface can be achieved. In the video, I showed two objects with different finishing onto them. First one is the welded pipe joint and the second one is the angle piece and onto both the pieces I show step by step method to do the grinding. Onto the angle piece, I start from 60 grit and ended up to 600 grit with various kinds of grit sizes because I divided the angle into different parts. If you have any question left definitely feel free to ask.

Help to translate video.

Learn Stainless Steel Grinding and Polishing on welded Joints,stainless steel polishing compound,stainless steel polishing tools,stainless steel,stainless steel welding,welding joints polishing,learn stainless steel,stainless steel grinding and polishing tools,stainless steel grinding wheels,angle grinder,stainless steel polishing,types of polishing compound,types of polishing pads,types of polishing wheels,types of grinding wheels,how to weld

DIY,howtomake,Invention,creative ideas,Recycling,tips and tricks,tutorial,ideas,inventor k,tin soldering,electric welding,electric welding method,solder with battery,sticky soldering,how to solder,tin solder,Even a NASA professor had to learn this from me! Idea of using 15V battery to weld aluminum brakes,aluminum welding,Aluminum welding technique,TIG welding,You will thank me for the rest of your life! Just a 1.5V battery will repair everything in your home

#POLISHING #WELDING #BUFFING

WELDING AND BUFFING PROCESS

WELDING AND POLISHING PROCESS

PROSESO NG PAG WELDING AT PAGBUFFING o POLISHING nang StainLess Steel

SOBRANG KINTAB MGA LODI PARANG HINDI WINELDING

stainless steel,weld cleaning

\

#WELDING

#BUFFING

#POLISHING

WELDING,BUFFING,POLISHING,FLEXIBLE FLAP DISC,SCOTCH BRITE DISC,HOW TO WELDING AND BUFFING,HOW TO POLISHING STAINLESS STEEL,PROCESS OF WELDING AND BUFFING

Stainless steel weld seam laser cleaning. Laser cleaning is a great way of preparing surfaces for painting after welding.

Laser used in a video is a 100W machine.

P-Laser develops and produces low to high power laser cleaning equipment for manual and automated production environment. Our systems are made for industrial applications like:

rust removal

grease removel

paint removal

weld (pre) treatment

mould cleaning

how to weld,beginner welding project,how to grind a weld,how to finish a weld,finish metal project,grind metal,how to use an angle grinder,victograin,polivlies,grinding disc,grinding disc use,variable speed grinder,how to make,welding,diy,diy table,art,welding finish,grinding steel,grind stainless,polish steel,lincoln electric,m18 grinder,best grinder,how to finish steel,how to sand steel,metal project,beginner welding,first welding project,metal

yeti,ymco,yeti machine company,yeti machine co,gvllow,chopper,choppers,harley,harley davidson,harley sportster,harley davidson sportster,sportster chopper,motorcycles,how-to,how to build a chopper,sporty,harley chopper,sportster 1200,mechanic,chopper build,hardtail,hardtail chopper,bike shop,welding,hardtail frame,custom motorcycle,custom chopper,fabrication,chopper fabrication,metal fabrication,tig welding,silicon bronze,finish weld,metal finishing

SECRET on How-To Clean Up WELDS

#stainlesssteelwelding #stainlesssteelpolishing #ambroscustom

हिंदी में समझने क लिए कैप्शन हिन्दी में ON कर ले ।

Stainless Steel Grinding and Polishing on welded joints is an important task for any fabricator. And as I said its a time-consuming process to make joint up to high gloss finish. The perfect way to do this work is by increasing gradually the number of grit. Usually, a good buffing surface appears after 1200 to 1500 grit. But unfortunately, I am not able to find those grit sizes from the local supplier. But by giving slightly more time to the 600 grit scotch Brite wheel almost near the perfect buffed surface can be achieved. In the video, I showed two objects with different finishing onto them. First one is the welded pipe joint and the second one is the angle piece and onto both the pieces I show step by step method to do the grinding. Onto the angle piece, I start from 60 grit and ended up to 600 grit with various kinds of grit sizes because I divided the angle into different parts. If you have any question left definitely feel free to ask.

Help to translate video.

Learn Stainless Steel Grinding and Polishing on welded Joints,stainless steel polishing compound,stainless steel polishing tools,stainless steel,stainless steel welding,welding joints polishing,learn stainless steel,stainless steel grinding and polishing tools,stainless steel grinding wheels,angle grinder,stainless steel polishing,types of polishing compound,types of polishing pads,types of polishing wheels,types of grinding wheels,how to weld

DIY,howtomake,Invention,creative ideas,Recycling,tips and tricks,tutorial,ideas,inventor k,tin soldering,electric welding,electric welding method,solder with battery,sticky soldering,how to solder,tin solder,Even a NASA professor had to learn this from me! Idea of using 15V battery to weld aluminum brakes,aluminum welding,Aluminum welding technique,TIG welding,You will thank me for the rest of your life! Just a 1.5V battery will repair everything in your home

#POLISHING #WELDING #BUFFING

WELDING AND BUFFING PROCESS

WELDING AND POLISHING PROCESS

PROSESO NG PAG WELDING AT PAGBUFFING o POLISHING nang StainLess Steel

SOBRANG KINTAB MGA LODI PARANG HINDI WINELDING

stainless steel,weld cleaning

\

#WELDING

#BUFFING

#POLISHING

WELDING,BUFFING,POLISHING,FLEXIBLE FLAP DISC,SCOTCH BRITE DISC,HOW TO WELDING AND BUFFING,HOW TO POLISHING STAINLESS STEEL,PROCESS OF WELDING AND BUFFING

Комментарии:

#TAEYANG x #Jimin #VIBEchallenge

TAEYANG

See What Works With Glance #trafficengineering

Applied Information Inc

Jhope, Jimin, Suga, Taehyung and Jungkook Run BTS Challenge.

Butter BTS k-pop

![Bitwig Studio 5.2 | The Complete Beginners Guide [ Full Course ] Bitwig Studio 5.2 | The Complete Beginners Guide [ Full Course ]](https://invideo.cc/img/upload/SW1oQVV2U0hHMEw.jpg)