Комментарии:

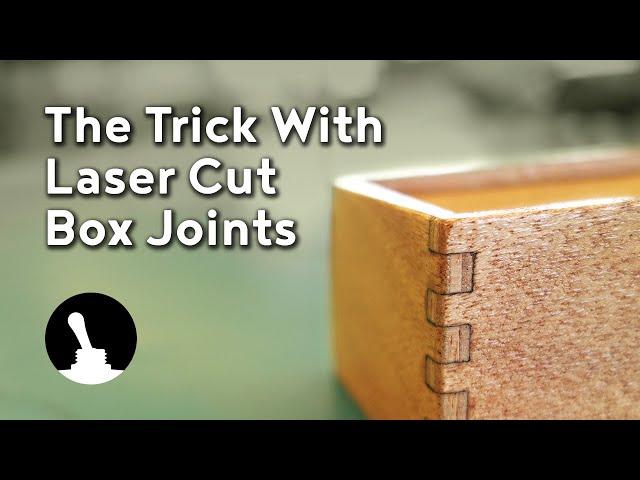

Great video, Thank you.

Ответить

Good practical advice!

Ответить

Couldnt you just make it so the box shares the same line so it only fits once and not need to measure kerf.

Ответить

Really nice video!

Ответить

Loved the “Don’t go ham on your sanding comment” awesome video and that box with the retro graphics turned out amazing.

Ответить

the bamboo wood I'm using has some flex to it (it doesn't lay flat), any tips on how to clamp them so they hold well? I'm creating a L-shaped divider for my partner's box

Ответить

What software do you use for design?

Ответить

I just wanna say how much awsome you re...great tutorial, best so far I watch !!!

Ответить

Hey brothers!!! Whats the name of the software?

Ответить

I am just starting out with a laser cutter. I will definitely look for the online box template. When you draw in Paint, how do you get the drawing over to the cutter? I am using Lightburn.

Ответить

Too much air blowing on surface when engraving. It is reburning the smoke/soot onto the surface. Run minimal air to just keep smoke off lens.

Ответить

I’ll do the moon thing. Howling I mean. Lengthening fingers and sanding after is so obvious once someone says it out loud.

Ответить

Great video.

Can you tell me what type of varnish was used?

(Composition and brand.)

Probably won’t get feedback on this but if you add 0.2mm won’t it make it wider than the board you’re hooking into? Cause you don’t do it on both right?

Ответить

Super nice box! Great tip on extending the fingers/ sand flush. Gives a really clean appearance.

Ответить

Great info!

Ответить

Brilliant video, so informative and really funny 😄

Ответить

wow! what maximum thickness your laser can cut through?

Ответить

impressive....

am a laser cutter machine operator, i just want to work away from home just in case of any job vacancies available

Very helpful and now subscribed because you have a great presentation style. 👍

Ответить

"Don't go too h.a.a.m. on the sanding" 😆🤣🤣

Ответить

Very well presented. Precise and instructive. Well done.

Ответить

Thanks for this. I started some laser finger joint box goodies a couple days ago. Wait, is google reading my mind? Whatever, great video. Now I need to get my belt sander up and running...

Ответить

Good job! Thanks for sharing the knowledge!

Ответить

thanks. I'm a Starrett fan as well, I'm going to do the same for some of my older tools that don't have boxes anymore :)

Ответить

i almost spit out my beer when i saw Windows 3.1, Paint do the box animation!

Ответить

Amazing video! Very useful tricks that can surely help a lot of people! ;)

Ответить

Wonderful!! Just what I was looking for! Thank-you for your excellent video. 👍🏻🤗

Ответить

Thanks for the helpful video man!

Ответить

Where did you shoot this intro? Heaven?

Ответить

Every time I have seen a video about making boxes using finger joints the person always directs you to some box generator on the internet. Where is the fun in that? Especially when it is so easy to design your own in LightBurn. The first box I made turned out perfect. I didn't even have to glue it together. By far, the best box making video I have seen.

Ответить

Excellent video, thank you. I usually apply the 2 in. yellow frog tape across the burn area especially the engraving portion. It greatly reduces the burn flare and is easy (but tedious) to remove.

Ответить

that graphic on the but joint :D

Ответить

Your video helped me a lot, thank you so much mate.

I'm planning to start my on small business in beekeeping and I would like very much to have your recommendation on which is the best laser cutting machine would be suitable for me to make Langstroth Beehive boxes made of 20mm thick Pinewood and Cedar Wood with finger joints shape.

Thanking you for your kind feedback in advance and best regards...

Great job

Ответить

Thanks for this! I really appreciate the information on accounting for kerf on the laser.. I'm trying to make some puzzles, and keef is definitely causing problems!

Ответить

I just stumbled across this video. Very well done! I have seen people use transfer tape on both sides of the wood to eliminate the soot and need to sand the pieces. Before I purchase a roll and try what are your experiences?

Ответить

Bonne idée des sur épaisseurs !!! Merci !

Ответить

Very instructive. Thanks !

Ответить

First time viewer and I just came across your channel, Great video, love the subtle (ok blatant) humour in your dialogue. Nice box too. Does the heat from lasering / lasing make the cut fingers more brittle? Would the soot layer need to be accounted for in cut calculations? Looked a bit tighter than I would attempt at a machine cut joint. Wouldn't want them to break easily !

Ответить

Are you using AutoCad to draw design for boxes?

Ответить

Well explained, to the point video. I am looking forward to make my own box 👏

Ответить

Amazing thanks for sharing

Ответить

nice. thanks

Ответить

My stepson and I have lasers. Very good video. Did you do the editing and FX too? How did you get that great accent? Where are good 3.4mm, 4mm wood sources in USA? Thanks.

Ответить

Great video thanks for sharing, had fun watching and learned something to boot.

Ответить

This will be very useful. I'm currently looking into using laser cut sheets of the following chipboard, laserboard, Basswood or MDF for building HO scale brick structures. I've been playing around with off sets in the CAD model to get reasonably tight fitting joints that don't go together too tight. Of course part of the problem is I'm using a 15 watt diode laser cutter. Chip board and Basswood cut just fine. In the end I'll probably stick with 1mm or .045" chipboard as the bricks scale out at 1.7mm/.046" from the centerline of the mortar joints. This way when joining wall sections in a row or at 90°s the courses of brick line up.

Off course on CNC machines depending on direction you can just specify the offset amount via the tool directory with G41 and G42 for left or right hand compensation.

I think this is one of the most satisfying videos to watch! 😊 If you're a little ocd, (like me) I like everything packed in a nice case in my workshop. Alas, not everything is available is a box, but with my new cnc router and newly added laser, I see some box making in my future... Nice video!

Ответить

Just awesome! Thanks

Ответить

![Прохождение Factorio: Space Exploration [17] - Космодром Прохождение Factorio: Space Exploration [17] - Космодром](https://invideo.cc/img/upload/VWI4ZjI1b0RJNUM.jpg)

![Houndeye [HL SFX] Houndeye [HL SFX]](https://invideo.cc/img/upload/NExaZUlUa2pZUU0.jpg)